Patent number 406,490

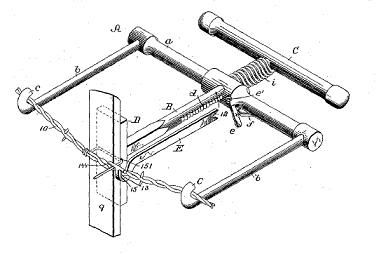

Another version of the same tool:

1616. A Brandt coin sorting/counting machine:

1617. A piece of hardware for a pulley, it's missing the sheave (wheel), the right end is flared so that if the rope breaks, a knot could be tied to repair it and it would still easily fit through the hardware.

1618. A Geyser Tube, used for the Coke and Mentos geyser experiment, to see it in action check out the video at the link.

1619. A coppersmith's spring faced planishing hammer, the two pieces are part of the spring face and snap over the head to soften the blows. This was used in one of a series of hammering steps to remove the hammer marks.

According to the "Art of Coppersmithing " by John Fuller, 1911:

When tinned and scoured it is ready for planishing, which is done on a bright side stake, with a small spring-faced hammer, Fig. 127 - that is, a hammer with an extra face of thin sheet steel, made and fitted as follows :

A piece of sheet steel, of a suitable thickness, in this case about 20 gauge, is cut, as shown in Fig. 128, the two ends turned up as in Fig. 129, to fit the hammer-face, the lugs being placed in a line with the handle. When fitted suitably lay between the hammer-face and the spring-face two or

three layers of French shalloon (lightweight wool), which answers as a cushion; now bind the lugs with a stout piece of binding wire, and turn the points of the lugs down on the wire in such a way that they will tend to draw the spring-face close up and tight to the hammer. After polishing, it is ready for use. The job must now be cleaned inside and out with a piece of nice soft rag, then commencing close up to the wiring edge with the hammer, begin to planish and follow each course around the body until the bottom is reached; then again clean it inside and out, and planish it over again to smooth and finish it.

See Fig. 127 on page 82 in the book.

Larger image

1620. A Hercules Powder Company Blasting Galvanometer, from this site:

Blasters check the continuity of their cap circuits with a blasting galvanometer, now sometimes called a blasting ohmmeter or blaster's multimeter. The Institute of Makers of Explosives (IME) defines these meters as follows: "Blasting Galvanometers and Blasting Ohmmeters are electrical resistance measuring devices designed specifically for the testing of electric detonators and blasting circuits. They may be powered by either a silver chloride cell or a dry cell with special current limiting circuitry so that the test current is below specified limits. Blaster's Multimeters are versatile, multipurpose test instruments designed to measure resistance and voltage in electric blasting operations. They can be employed for measuring stray current."

To submit photos, send them to the address in my profile.

Last week's set is seen below, click here to view the entire post.

More discussion and comments on these photos can be found at the newsgroup rec.puzzles. Glenwood Gardens Park

No comments:

Post a Comment